Strain Gage measurement: what is it

The strain gage measurements are a method in order to measure the strain to which a body is subject and the strain gages are the main tool. The strain gauges are transducers used for measurement of the average strain, in the neighborhood of a point and in a given direction, of materials subjected to mechanical stresses or thermal. From the measured strain is possible to calculate the stresses of the component under test.

General Information Request

STRAIN GAGE MEASUREMENTS:

ELECTRICAL RESISTANCE STRAIN GAGE

There are different types  of strain gages, which work according to different measurement principles.

of strain gages, which work according to different measurement principles.

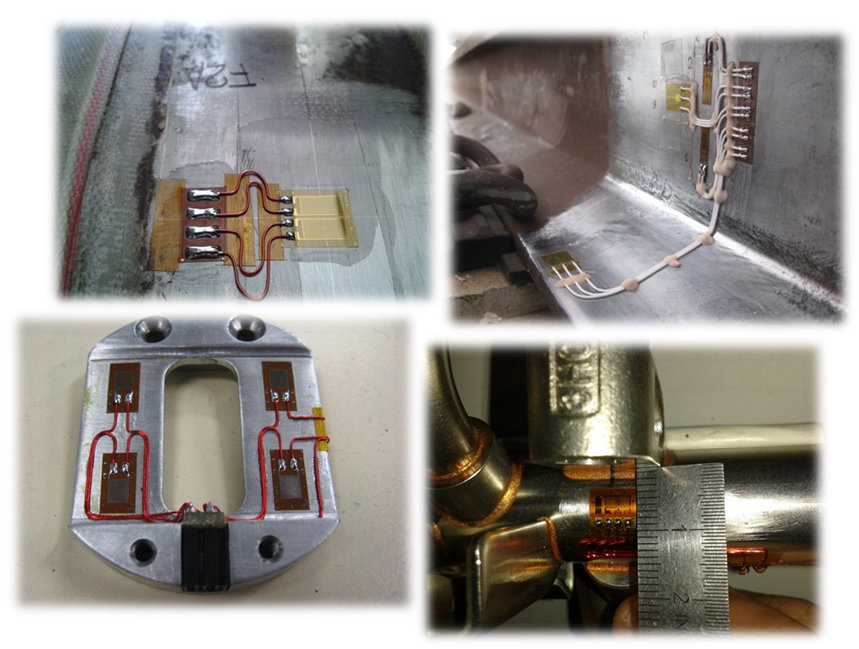

The most widespread is the electrical resistance strain gage (SG), where a particular alloy grid (Constantan or Karma) change its electrical resistance proportionally to its elongation. Usually, the resistance variation of the SG is measured by the Wheatstone bridge. These SG are used for the experimental stress analysis on the structures, and also for the realization of transducers for the measurement of mechanical quantities, such as pressure transducers and load cells.

STRAIN GAGE MEASUREMENTS:

RELATIONSHIP BETWEEN ELECTRICAL RESISTANCE AND STRAIN

The strain gage measurement is a method that allows to calculate the stresses to which a component of any material is subject, starting from a strain measurement.

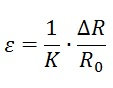

The average strain is calculated by the measurement of the variation of electrical resistance undergone by the grid of the SG installed on the component under test, by the following relationship:

where:

- K gauge factor of the SG.

- ΔR change in resistance of the installed SG

- R0 initial resistance of the installed SG.

STRAIN GAGE MEASUREMENT: SPECIAL APPLICATIONS

- High temperature applications

- tie rods for the steel industry

- Applications on special material (composite materials, stone, etc.)

- carbon fiber paddle handle

- rear rotor helicopter blade

- marble columns

- specimens stone (marble and tuff)

- Human tooth

- Miniaturized application

- Metering rod for internal-combustion engine

- Needle for dental use

- Installations on rotating components

- couplings (for torque measurements)

- centrifugal compressor impellers

- spindle coupling metal rolling mill

- Installation on pressurized components

- dryer cylinder for paper industry

- manifold prototype

- diesel engine common rail

- centrifugal compressor casing

- moist-heat industrial sterilizers for food industry

- CNG tanks for bus

- Transducers (load cells, etc.)

- Installations submerged

- centrifugal compressor casing

- centrifugal pump

- Thermal characterization of strain gauge installations

- specimen tie rod for steel industry

- steel specimens for thermal characterization

- natural ventilation laboratory oven

STRAIN GAGE MEASUREMENT: APPLICATION FIELDS

The strain gage through the SG is a method for points suitable for the measurement of elastic and plastic strain on any material. The typical resolution is 1 μm/m, while the measurement range is typically between 5000 and 50000 μm/m (up to 200,000 μm/m with special SG). The method is suitable for the strain measurements even at low and high temperatures and in hostile environment.

This technique is widely used in many fields, among which:

- stress experimental analysis

- residual stress analysis

- torque and torsional vibration measurements

- experimental modal analysis

- stresses dynamic analysis

- pressure vessels