Residual stress software

Residual stress measurements require to process all data acquired during a residual stress test.

SINT Technology, a company specialized in testing, analysis and diagnostic services applied to stress, vibration and noises, designed and developed the EVAL 8, a specific residual stress software fully compliant to the ASTM E837 standard for hole drilling measurements.

Moreover SINT Technology, thanks to its highly qualified laboratory, provides highly qualified software and services for a wide variety of industrial applications for measurement, inspection and automation.

The main fields of application for the software that SINT Technology develops are:

- Strain gauge and residual stress measurements

- Acquisition of data for vibration and noise analysis

- Acquisition and processing of the thermodynamic parameters for testing and monitoring machine and plant performance

- Balancing of rotating machinery

- Test facility automation

- Precision static data logging

- High frequency data logging

EVAL 8: RESIDUAL STRESS ANALYSIS SOFTWARE

SINT Technology has a wide range of measurement products that are provided with software systems for a perfect operation. The experience gained in the measurement field has been essential to develop support software for even complex measurement systems.

One of these is the EVAL, a residual stress analysis software, recently updated from the 7 version (EVAL 7) to the 8 one (EVAL 8).

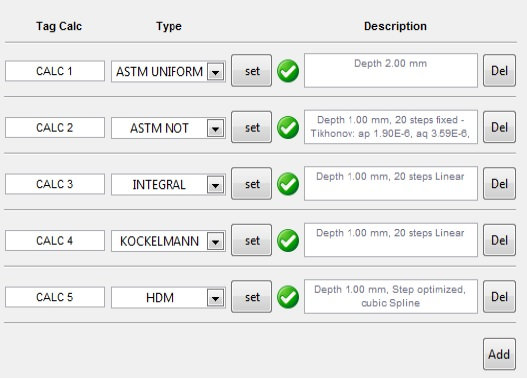

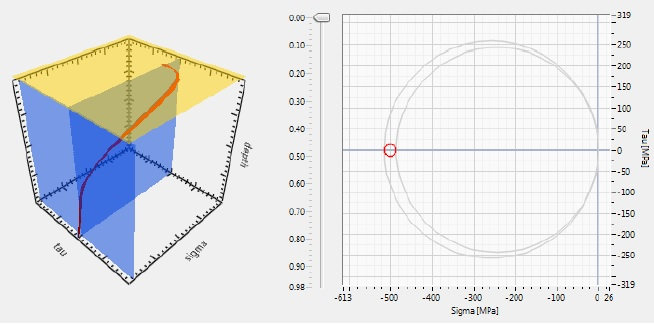

Compared to the EVAL 7, in the EVAL 8 the standard algorithms are improved with additional features and a better graphical overview including a further database of strain gage rosettes and materials. Moreover, a new theoretical algorithm, named HDM, has been implemented: this model is able to provide a further analysis of the residual stress field that improves even more the standard residual stress analysis.

At last, the EVAL 8 software is fully compliant to the new version of the ASTM E837 standard.

This updated residual stress software, with its new graphical layout, makes easier, intuitive and sequential the calculation process during a residual stress analysis, especially when it requires a long time and several repetitions: all these new features make the EVAL 8 software an essential tool for all residual stress measurements.

General Information Request