Residual stress in composite materials

The MTS3000-Restan is a product developed by SINT Technology. It is a residual stress analyzer system, used to measure residual stresses inside several materials.

With a modification of the standard system, it can be used to measure residual stresses in composite materials, too.

A composite material is a material composed of at least two elements working together to produce material properties that are different to the properties of those elements on their own. In practice, most composites consist of a bulk material (the ‘matrix’), and a reinforcement of some kind, added primarily to increase the strength and stiffness of the matrix. This reinforcement is usually in fibre form.

The MTS3000 – Restan is an automatic system that use the hole-drilling strain-gage method, according to the ASTM E837 standard.

HOW DOES MTS3000 – RESTAN WORK ON COMPOSITE MATERIALS?

The MTS3000 – Restan is able to perform a complete test, including drilling process, centering and evaluating hole diameter and eccentricity. This is possible thanks to an optical-mechanical head controlled by an electronic control unit and a specific software. At the end of the test, it’s possible to get a complete test report and to calculate the residual stress results choosing among several options.

General Information Request

HOW TO MEASURE RESIDUAL STRESS ON COMPOSITE MATERIALS?

A special version of the MTS3000 – Restan System can be used to determine residual stress in composite materials. Composite material is not uniform and different results are expected in different points of the same sample.

The system is equipped with an electronic device that makes this test completely automatic, easy and fast; moreover, residual stress are measured without melting material and without local burning.

Restan MTS 3000 is actually the ONLY system in the world specifically designed to carry out these tests, thanks to a modification of the standard drilling technology. Drilling is done at low speed (some thousands of RPM) in order not to generate local heat in the material. It also use a reduced feed speed to minimize the effect of drilling (approx. 0.1 mm/min).

The system is equipped with an electronic device that makes this test completely automatic, easy and fast; moreover, residual stress are measured without melting material and without local burning.

Other advantages using MTS3000 system for composite materials are:

- Fully automatic drilling system

- Fully automatic acquisition system

- Higher precision in drilling the hole

- Smaller uncertainty in residual stress measurement

- Different options for the calculation of the residual stress results

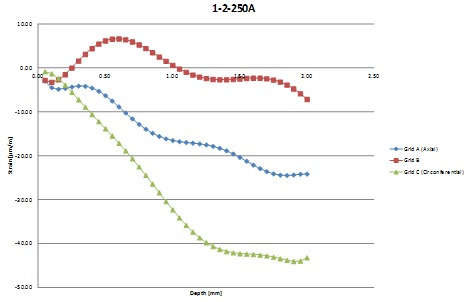

TEST RESULT WITH MTS3000 – RESTAN FOR COMPOSITE MATERIALS

In case of residual stresses on composite materials, the test will show a not uniform trend of residual stress, although generally the ASTM result for uniform stress provides a quick and easy estimate of the residual stress in the test material. Increasing the delay time allows the signal stabilization so that the test results are really accurate.

KEY FEATURES OF MTS3000 – RESTAN FOR RESIDUAL STRESS IN COMPOSITE MATERIALS:

- Custom-speed drilling technology

- Simple, automatic and fast to use

- Suitable for on-site and laboratory applications

- Evaluation of residual stresses as a function of depth

- Facility to accurately perform drilling steps up to some microns in the depth

- Choice of back-calculation methods