Residual stress Analyzer

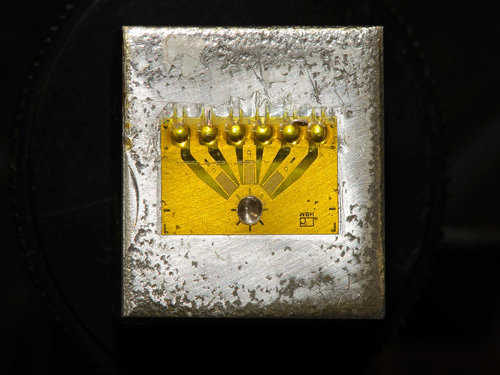

SINT Technology produces, develops and sells the Residual Stress Analyzer (RESTAN). This system consists of an optical-mechanical device controlled by a specific software program that runs by an electronic control unit. The heart of the residual stress analyzer system is the optical-mechanical head that houses both the drilling system and the system for centering and evaluating the hole diameter and eccentricity.

The high speed turbine of the residual stress analyzer rotates at very high speed (400000 RPM): in this way, no stresses are induced in materials during testing. Moreover, the stepping motor, controlled via software, allows accurate and micrometric drilling steps with hole profiles that can also be hyperbolic shaped; this ensures the maximum measurement accuracy.

The test is programmed through the software RSM and is fully automatic; the elaboration of the results is made by the software EVAL.

General Information Request

The residual stress analyzer system offers two advantages:

- The possibility of conducting the acquisition stage in a flexible way by automatic management of the test conditions that better suit specific requirements.

- The fast back-calculation of the residual stress from the recorded measurements by the use of complex algorithms that permit a comparison with several different calculation methods. The most important is the method in accordance with the ASTM E837-13, that is the only standard on residual stresses available in the world.