Residual stress

All forces that act on materials in absence of external solicitations, at uniform temperature conditions, are defined as residual stress forces. Components and materials are often influenced by those residual stress forces: they change materials structure, affecting their strength and crack resistance. With on site and on lab analysis we can check the structural and dimensional stability of mechanical components and their resistance: that’s why it is very important to measure residual stresses in deep.

WHAT IS A RESIDUAL STRESS?

Residual stress is pretty similar to a load stress: it means that the residual stress compromises materials structural and dimensional stability. In other words, it compounds the system behavior.

Residual stress gradually reduces load capacities and the safety of mechanical components during common operations; it is therefore clear that residual stress analysis is important in mechanical design engineering as it can prevent mechanical equipment failures.

General information Request

TRAINING ON STRAIN GAGE AND RESIDUAL STRESS MEASUREMENTS

SINT Technology offers training about strain gages and residual stress applications both in the laboratory or directly in the companies. The training courses are divided in theoretical lessons and practical installations of strain gages and measurements with the main residual stress methods.

More info also here: Measurement of Residual Stresses

RESIDUAL STRESS CAUSES

Residual stresses can be caused by:

- non-uniformity through the thickness of materials, due to heat treating during metal hardening

- non-uniform heating of metals during casting or cooling

- welding or forging processes

- machining

- reheating

SINT Technology is a laboratory specialized in strain gage residual stress measurements, in particular the Hole Drilling Method. Other most significant experience is in:

– Sachs’ boring-out method

– Layer removal

– Sectioning

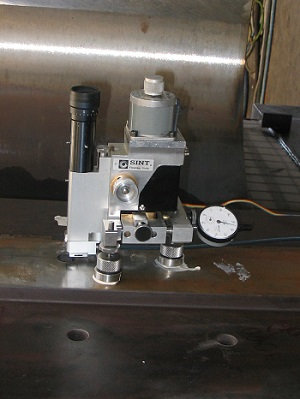

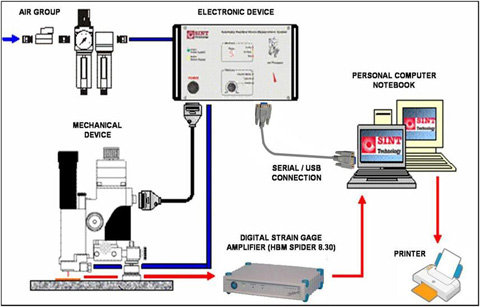

– Ring core method

For the Hole Drilling method, SINT Technology has developed and patented a system for measuring residual stress (MTS3000 – Restan), internationally marketed by HBM. It is one of the more efficient non-destructive method to determine residual stresses on materials. The MTS3000 – Restan is able to measure residual stresses into metals and other kinds of materials. It is composed by a mechanical – optical fixture and an electronic device with a set of accessories and spare parts, in particular turbines and drills, connection cables, set of tools, software protection key, dial gages, manometer and pressure regulator with air filter, manuals and software installation CD. The system permit to drill the material at 400,000 rpm: this avoid introducing any other residual stress into the material during the test process.

In this case, the residual stress measurement procedure involves the following steps:

In this case, the residual stress measurement procedure involves the following steps:

-

- Installation of the strain gage rosette with three radial grids on material;

- a through hole or a blind hole is drilled through the geometric center of the rosette;

- readings are made of the strains produced by relieving the residual stresses.

-

- To follow in details all test steps and to collect all data,

MTS3000 – Restan

- is provided with a small computer or tablet PC including pre-installed software.