MTS3000 – Restan

The MTS3000 – Restan is an automatic system for measuring residual stresses by the hole drilling method.

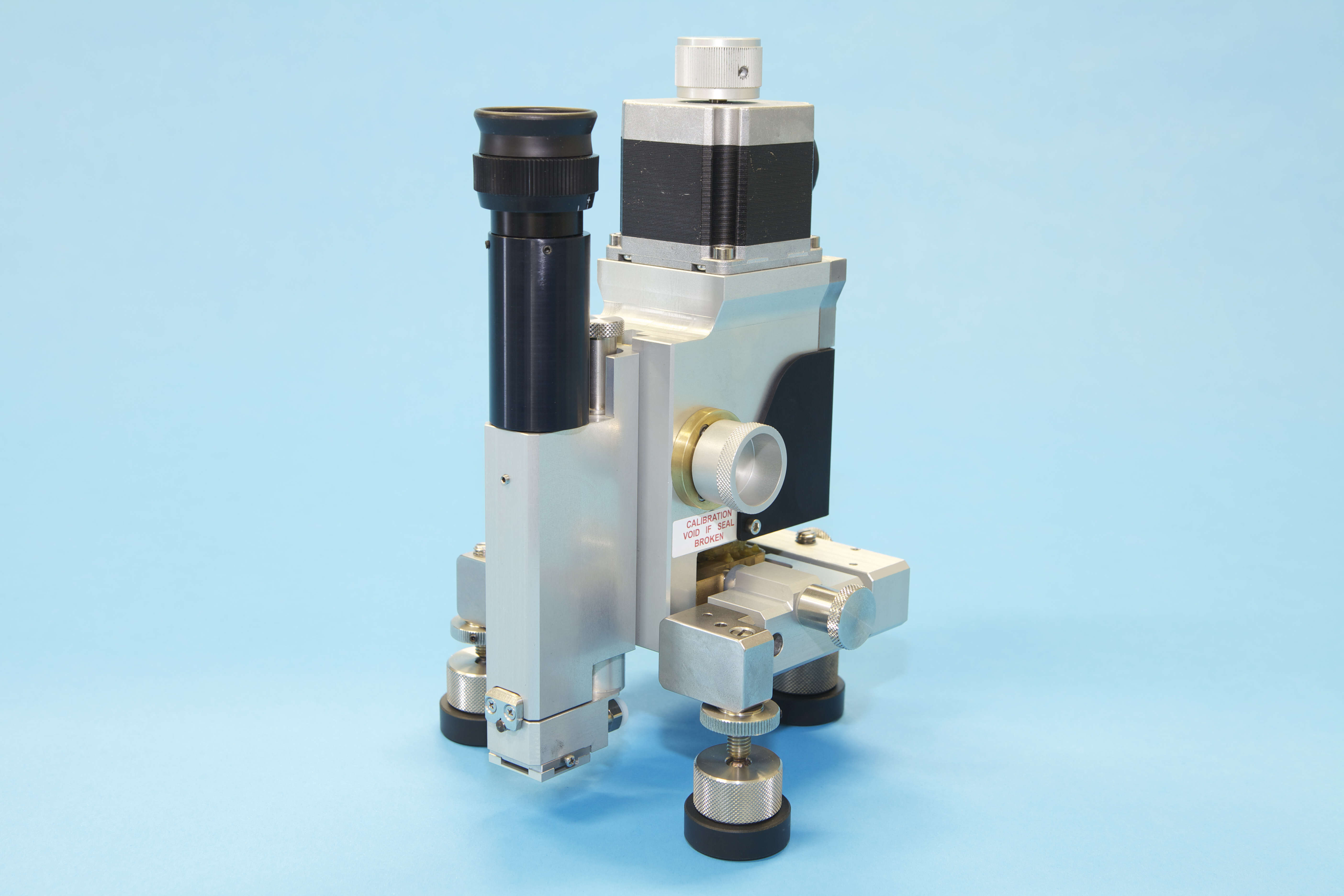

The system consists of an optical-mechanical system, an electronic control unit, hole drilling operating and control software and reprocessing software.

Once the MTS3000 is placed on the component to be examined, the drilling device is adjusted in the X and Y directions by two setting screws. This brings the cutter exactly over the rosette, thanks also to the microscope with cross-hair pointer.

The MTS3000 cutter can be quickly brought to its starting position in the Z direction by manual adjustment. An electric contact allows to determine the exact zero-point of the material.

The hole is realized with a high-speed air turbine (350000 RPM), so that no stresses are induced into the material during the drilling process.