Why field testing on centrifugal compressor

Rather than just a contractual requirement, field performance testing of centrifugal and reciprocating compressors can be a valuable opportunity to assess the base line of the unit once it is placed in operation. This can be true for both new and revamped units, and can help management in making production plans according to the real capabilities of the machine.

Very often, new compressors undergo a shop test before being shipped to site. This should determine the gap between expected design performances and “as-tested” ones, due to the manufacturing process. Why should the performance test be repeated in site?

The main reasons to conduct a field performance test are:

- determine the actual performance characteristics and suitability for service of the unit when it is installed in the pipeline

- verify the behaviour of the compressor once it is coupled with other components, such as coolers and scrubbers and the pipeline itself.

- verify if the compressor meets the specifications of the applicable purchase contract, therefore if liquidated damages or “make good” actions are required

Moreover, according to ASME PTC 10 code, shop tests often belong to the “Type 2” category, i.e. the test has been performed using a gas different from the contractual one. Field performance testing allows to use the proper process gas, which design compressor characteristics are based on.

General Information Request

LET US HELP YOU

SINT Technology is a reliable and independent supplier of compressors performance test, which can help you in the continuous monitoring of your machine and in the assessment of its condition, in terms of head, efficiency and absorbed power.

SINT Technology has been conducting performance and acceptance test on centrifugal and reciprocating compressors since several years.

Customer is supported both in the early contractual phase and prior to start the commercial operation of the unit by verifying the fulfilment of guaranteed items.

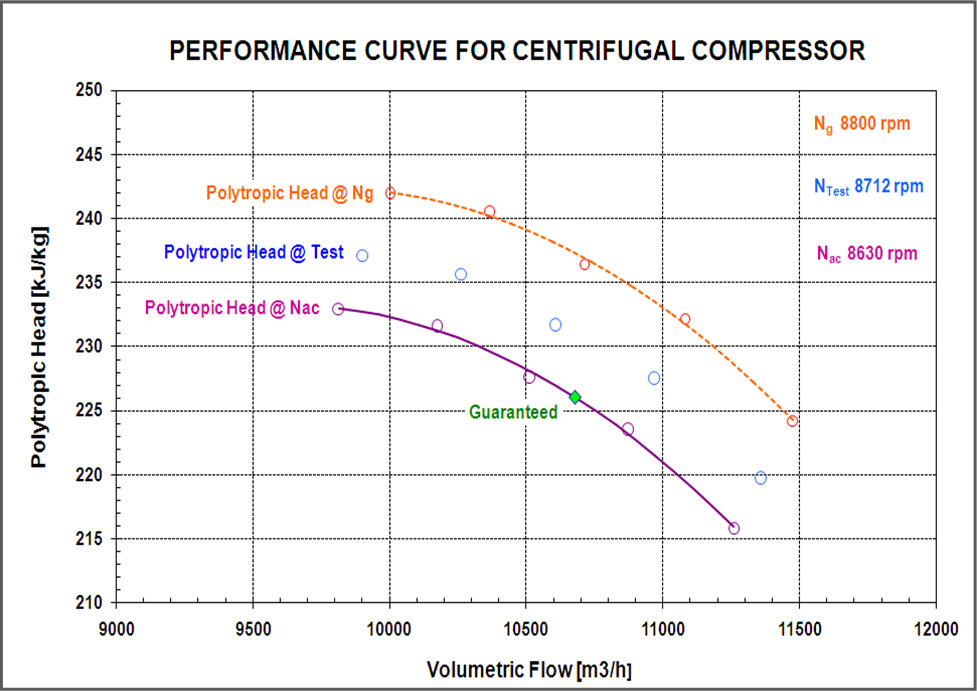

Relevant test documentation for API compliant compressors can be produced upon Customer’s request. A detailed compressor test procedure can be issued based on available datasheet and shop-test curves, explaining the method to compare actual compressor performances to guaranteed ones.

SINT Technology can also control the relative performance throughout the life of the compressor by periodic verification, in order to help Customer in prevent major failures. SINT Technology can also provide acoustic surveys and vibration measurements .

Our expertise in the business has lead us to be the first Italian laboratory in obtaining the official recognition from ACCREDIA, the Italian National Accreditation Body, for centrifugal compressors performance tests. This ensures and certifies the quality of our testing results to all our Customers. Our standards are set by major international codes, such as ASME PTC 10, ISO 5389 and ISO 1217.

SINT Technology provides global solutions for compressor performance testing on all kind of sizes, including:

- Single stage compressor

- Multistage compressors and compression trains