Reciprocating compressor diagnostics

Reciprocating compressor diagnostics are important for checking the reciprocating compressor machine conditions in order to pinpoint behavior changes, preventing machine faults.

Reciprocating compressor diagnostics provide the following benefits:

-

better programming of maintenance services

-

reducing forced outage risks

-

improving machine performance

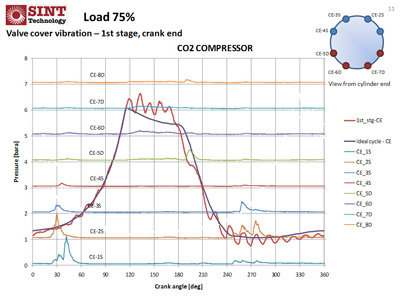

One of the main techniques used in reciprocating compressor diagnostics is the absolute pressure versus piston displacement analysis that allows to check reciprocating compressor efficiency and to detect undesired behaviors.

SINT Technology can provide a wide range of reciprocating compressor diagnostics including also vibration and torsional vibration measurements.

General Information Request

SUBSCRIBE TO SINT-TECHNOLOGY NEWSLETTER

[contact-form-7 404 "Not Found"]