Torsional vibration measurements and analysis

Torsional vibration causes oscillatory angular stresses which, added to normal rotational motion, result in drive shaft torsion. That is the reason why the torsional vibration analysis and measurements are important in an industrial context.

Torsional vibrations can produce:

- High gear noise

- Faster gears wearing and tearing

- Gear failure

- Slippage of coupling hubs

High values of torsional vibration measurements can therefore have disastrous effects by causing damage to equipment, plant, staff and by generating a negative impact to production.

HOW TO MEASURE TORQUE AND TORSIONAL VIBRATION

SINT Technology, thanks to its advanced systems of measurement and processing software, is able to perform torsional analysis on a wide range of machines.

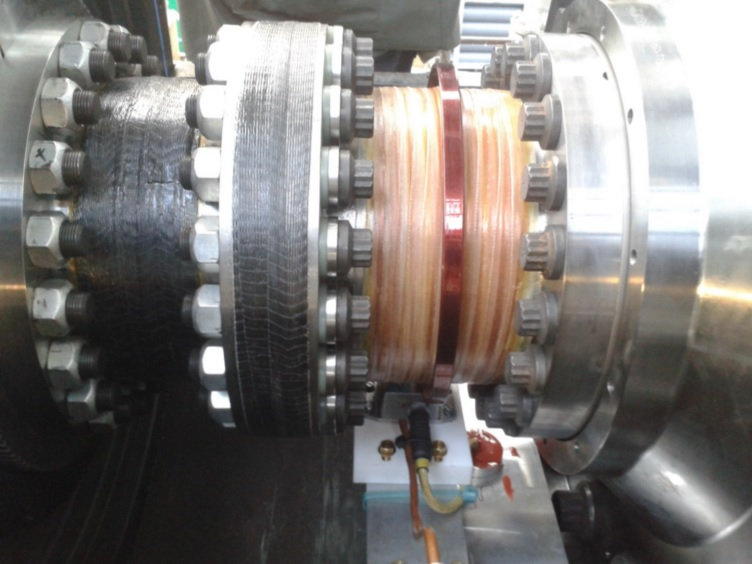

We have developed an integrated telemetric acquisition system for torque and torsional vibration measurements.

The software peculiarity is the possibility of carry out time and spectrum analysis and three-dimensional waterfall analysis as well.

In addition to telemetric system for signal transmission, torsional vibration measurements require a bridge arrangement of four strain gauge fitted at 45°. Such a configuration compensates both flexural strength and temperature variations. The acquired signal, obtained by this kind of torsional vibration measurements, is proportional to the strains that are significant for shear stress and torque estimation.

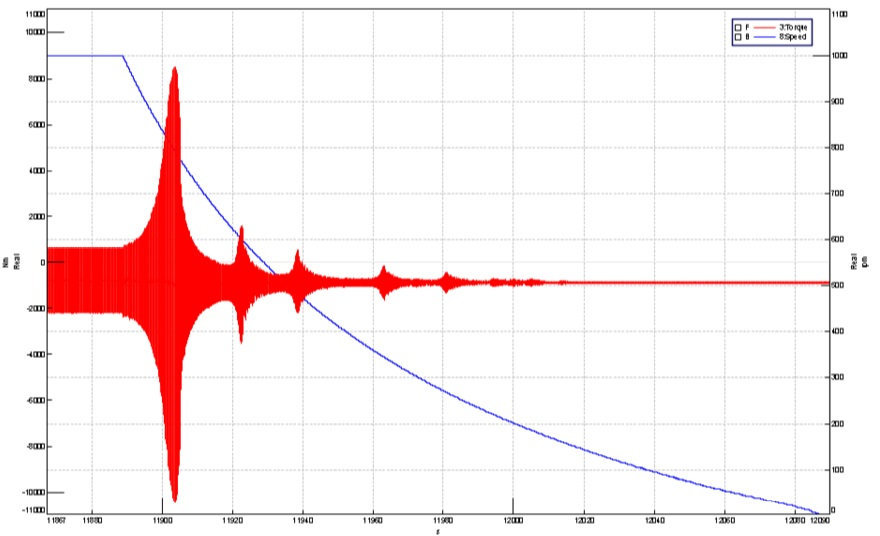

Torsional vibration: reciprocating compressor shut down – Time domain analysis

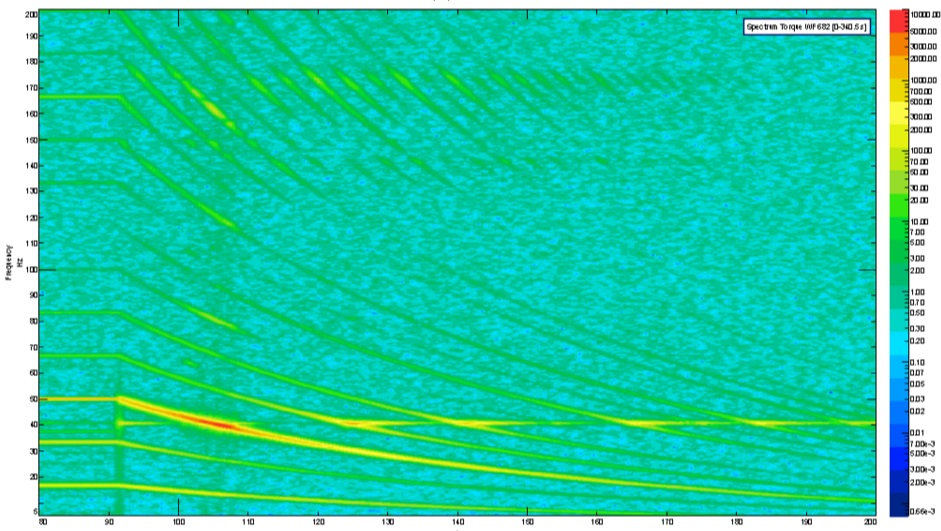

Torsional vibration: reciprocating compressor shut down – Frequency domain analysis

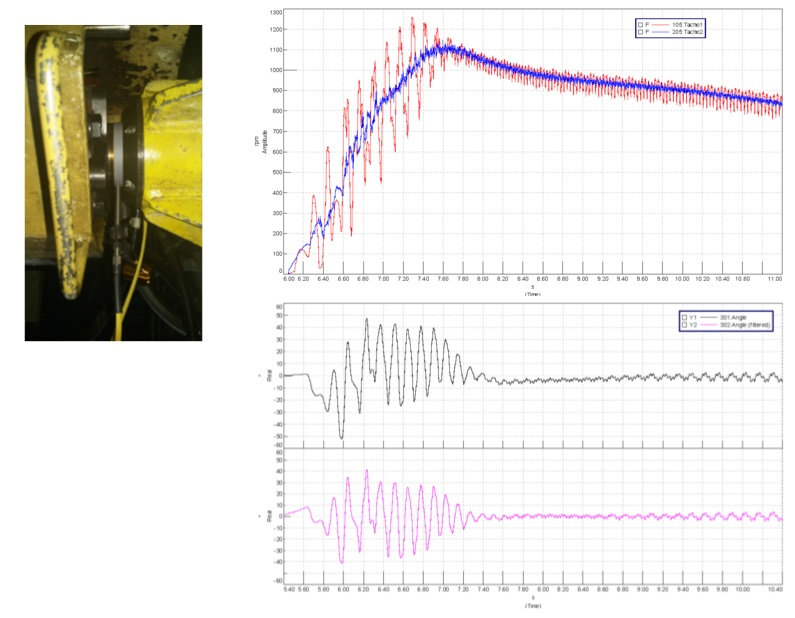

Tosional vibration with zebra-tape in automotive test bench